Thermal Performance of Modern Windows: Revolutionizing Home Energy Efficiency

The Thermal Revolution: Modern Windows Redefined

In an era defined by escalating energy costs and a heightened awareness of environmental impact, the thermal performance of windows has moved from a niche concern to a central consideration for homeowners and builders alike. Modern windows are no longer mere apertures for light and views; they are sophisticated components of a building’s thermal envelope, engineered to minimize heat transfer and maximize energy efficiency. The shift reflects a growing understanding that windows significantly impact heating and cooling costs, often accounting for 25-30% of residential energy consumption, according to the U.S.

Department of Energy. Consequently, investing in energy-efficient windows is not merely an aesthetic choice but a strategic financial decision, enhancing home value and reducing long-term operational expenses. This article delves into the science, technology, and practical implications of thermal performance in modern windows, examining the latest innovations that are transforming how we heat and cool our homes. Specifically, the advancements in energy-efficient windows offer homeowners a tangible pathway to reduce their carbon footprint and enhance indoor comfort.

Features such as low-E glass coatings, which minimize radiative heat transfer, and argon gas-filled panes, which reduce conductive heat transfer, are now standard in many new window models. These technologies directly address the primary mechanisms of heat loss and gain, leading to substantial improvements in a window’s U-factor, a key metric indicating its insulation capability. For example, replacing single-pane windows with ENERGY STAR certified windows can reduce energy bills by 12-15% annually, translating to hundreds of dollars in savings, depending on climate and home size.

The initial investment in window replacement is often recouped through these energy savings over time, making it a compelling home improvement project. Furthermore, the choice of window frame materials significantly impacts overall thermal performance and contributes to the long-term durability of the window. While traditional aluminum frames are known for their strength, they are also highly conductive, requiring thermal breaks to prevent heat transfer. Vinyl frames, on the other hand, offer excellent insulation properties and are relatively low-maintenance, making them a popular choice for homeowners seeking energy efficiency and cost-effectiveness. Wood frames, while aesthetically appealing, require regular upkeep to prevent rot and maintain their insulating capabilities. The selection of the appropriate window frame material, coupled with professional window installation to ensure a tight seal and minimize air leaks, is crucial for maximizing the thermal benefits of modern window technology and achieving a truly sustainable building envelope.

Decoding Thermal Performance: Key Metrics and Standards

The primary function of a window, viewed through the lens of thermal performance, is to act as a selective barrier, carefully regulating the transfer of heat into and out of a building. This ability is quantified using several key metrics, each offering a unique perspective on a window’s energy efficiency. The U-factor, perhaps the most universally recognized, measures the rate of heat transfer through the entire window assembly – encompassing the frame, glass, and any intervening air spaces.

Expressed in BTU/hr-ft²-°F (or W/m²-°C), a lower U-factor signifies superior insulation, indicating that less heat escapes during winter and less heat enters during summer. For homeowners considering window replacement as a home improvement project, understanding U-factor is paramount; opting for energy-efficient windows with low U-factors directly translates to reduced heating and cooling costs. Solar Heat Gain Coefficient (SHGC) focuses specifically on solar radiation, quantifying the fraction of solar heat admitted through a window. This metric is crucial in warmer climates, where minimizing solar heat gain can significantly reduce cooling loads and improve indoor comfort.

A lower SHGC indicates that the window blocks more solar heat. For example, a homeowner in Arizona might prioritize windows with a low SHGC to prevent excessive heat buildup inside their home, thereby lowering air conditioning expenses. Conversely, in colder climates, a higher SHGC might be desirable to harness solar heat for passive heating during the winter months. Visible Transmittance (VT), on the other hand, measures the amount of visible light that passes through the window, influencing the need for artificial lighting.

Balancing SHGC and VT is essential for optimizing both energy efficiency and natural illumination. Air Leakage (AL), measured in cubic feet per minute per linear foot of window crack (cfm/ft), indicates the amount of air infiltrating through the window assembly. High air leakage contributes to drafts, inconsistent temperatures, and increased energy consumption, as conditioned air escapes and unconditioned air enters the building. Stricter energy efficiency standards increasingly emphasize the importance of low air leakage ratings.

Modern, energy-efficient windows incorporate advanced sealing technologies and tighter construction methods to minimize air infiltration. For homeowners undertaking window replacement, ensuring proper window installation is critical to achieving the advertised AL rating; even the most energy-efficient windows will underperform if installed improperly. Understanding these metrics, in conjunction with factors like window frame materials and low-E glass options, empowers homeowners to make informed decisions when selecting windows tailored to their specific climate conditions, energy goals, and home improvement objectives. Industry standards, such as those set by the National Fenestration Rating Council (NFRC), provide standardized testing and labeling to help consumers compare window performance across different manufacturers.

Glass Technology: The Cutting Edge of Insulation

Advancements in glass technology have revolutionized window thermal performance, transforming them from simple panes into sophisticated energy management systems. Low-E (low-emissivity) coatings, now a standard feature in energy-efficient windows, are microscopically thin, virtually invisible metallic layers applied to the glass surface. These coatings selectively reflect infrared radiation, the primary culprit in heat transfer, keeping homes cooler in summer by reflecting solar heat and warmer in winter by retaining interior heat. The effectiveness of Low-E glass is quantified by its Solar Heat Gain Coefficient (SHGC); lower SHGC values indicate less solar heat is admitted.

For homeowners in warmer climates, selecting windows with a low SHGC is crucial for minimizing air conditioning costs. Conversely, in colder climates, a higher SHGC might be desirable to harness passive solar heating. Multiple panes of glass, often referred to as double- or triple-pane windows, further enhance window insulation. The spaces between the panes are typically filled with inert gases like argon or krypton, which are denser than air and possess lower thermal conductivity. Argon gas windows, for example, significantly impede conductive heat transfer compared to air-filled windows, contributing to a lower U-factor and improved overall thermal performance.

The U-factor, a key metric for evaluating window insulation, measures the rate of heat transfer; lower U-factors signify better insulation. Selecting windows with the appropriate number of panes and gas fill is essential for optimizing energy efficiency and comfort in your home. For window replacement projects, understanding these specifications is paramount to achieving desired energy savings. Beyond Low-E coatings and gas fills, suspended film technology represents another leap forward in window insulation. This technology utilizes a thin, transparent film suspended between the panes of glass, creating additional insulating air spaces and further reducing heat transfer.

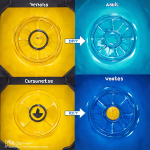

Dynamic glass, including electrochromic and thermochromic options, offers even more sophisticated control over solar heat gain and glare. Electrochromic windows, for example, can be electronically tinted on demand, while thermochromic windows automatically adjust their tint in response to sunlight intensity. These dynamic solutions optimize energy efficiency by minimizing the need for artificial lighting and reducing cooling loads. When considering home improvement projects focused on sustainable building practices, these advanced glass technologies offer compelling benefits, contributing to significant long-term energy savings and enhanced comfort.

Frame Materials: Insulation, Durability, and Design

The frame material plays a critical role in overall thermal performance, acting as a crucial bridge between the glass and the building structure. While the glazing significantly impacts a window’s U-factor and Solar Heat Gain Coefficient (SHGC), the frame’s contribution to window insulation cannot be overlooked. Wood frames, celebrated for their natural beauty and inherent insulation properties, demand consistent upkeep to prevent rot and insect damage, especially in humid climates. Vinyl frames, a popular choice for energy-efficient windows, offer a compelling blend of affordability, low maintenance, and excellent thermal resistance.

Their resistance to moisture and decay makes them a durable option, reducing the need for frequent window replacement. Aluminum frames, known for their strength and structural integrity, present a thermal challenge due to their high conductivity. However, modern aluminum frames often incorporate thermal breaks – insulating materials strategically placed within the frame to disrupt heat flow, significantly improving their thermal performance. Fiberglass frames represent a step up in both performance and durability, making them a favored option for homeowners seeking long-term value.

Their composition allows them to expand and contract at a rate similar to glass, reducing stress on the seals and minimizing the risk of air leaks, which are detrimental to window insulation. This stability, combined with inherent resistance to warping and corrosion, translates to a longer lifespan and reduced maintenance costs. Furthermore, fiberglass frames can be manufactured with hollow cavities that can be filled with foam insulation, further enhancing their thermal performance and contributing to lower energy bills.

Many sustainable building projects specify fiberglass frames to meet stringent energy efficiency standards. Composite frames represent an innovative approach, blending different materials to leverage their individual strengths and compensate for weaknesses. For instance, a composite frame might combine a wood interior for aesthetic appeal with a fiberglass exterior for weather resistance and low maintenance. Another common combination involves wood and vinyl, strategically placed to optimize insulation and durability while managing costs. The key advantage of composite frames lies in their ability to offer a tailored solution, addressing specific performance requirements and aesthetic preferences. When evaluating window frame materials, homeowners should consider not only the U-factor and SHGC ratings but also the long-term maintenance requirements, durability, and aesthetic compatibility with their home’s architectural style. Consulting with a window installation professional can provide valuable insights and ensure the optimal choice for maximizing energy savings and comfort. For example, exploring green mortgages can be a way to finance energy-efficient window upgrades.

Installation and Design: Maximizing Thermal Efficiency

Proper installation is paramount to realizing the full thermal performance potential of modern windows. Gaps and air leaks around the window frame can negate even the most advanced glass and frame technologies, rendering features like low-E glass and argon gas fills virtually useless. Professional window installation ensures that windows are properly sealed and insulated, minimizing air infiltration and maximizing energy savings. This often involves using specialized expanding foam and weather stripping to create an airtight barrier, a critical step often overlooked in DIY installations.

According to the U.S. Department of Energy, air leaks can account for up to 30% of a home’s heating and cooling costs, highlighting the importance of meticulous installation practices for energy-efficient windows. Therefore, investing in certified installers is an investment in long-term savings and comfort. Furthermore, the orientation of windows significantly affects their thermal impact. South-facing windows receive more solar heat gain in winter, which can be advantageous in colder climates, reducing heating bills. However, east- and west-facing windows can contribute to overheating in summer, increasing the demand for air conditioning.

Strategic window placement, coupled with appropriate shading strategies such as awnings, overhangs, or strategically planted trees, can optimize thermal performance and reduce energy consumption. For instance, homeowners in warmer climates might consider installing windows with a lower Solar Heat Gain Coefficient (SHGC) on east- and west-facing walls to minimize unwanted heat gain. Careful consideration of these factors during the design or window replacement phase is crucial for maximizing energy efficiency. Beyond orientation and installation, the choice of window frame materials and the overall window design play a vital role in long-term thermal performance and sustainability.

For example, while aluminum frames are known for their strength and durability, their high thermal conductivity can compromise window insulation. Opting for aluminum frames with thermal breaks or choosing alternative materials like vinyl or fiberglass can significantly improve the U-factor of the window assembly. Similarly, the design of the window, including the number of panes and the type of gas fill used, should be carefully considered based on the specific climate and energy efficiency goals. Investing in high-quality, energy-efficient windows with proper installation and strategic design is a key component of sustainable building and home improvement, contributing to both reduced energy consumption and increased home value.

A Sustainable Future: Investing in High-Performance Windows

The evolution of window technology has ushered in an era of unprecedented thermal performance. By understanding key metrics like U-factor and Solar Heat Gain Coefficient (SHGC), embracing advanced glass technologies such as low-E glass and argon gas fills, selecting appropriate window frame materials, and prioritizing professional window installation, homeowners and builders can significantly reduce energy consumption and enhance comfort. As energy costs continue to rise and environmental concerns intensify, investing in high-performance, energy-efficient windows is not only a sound financial decision that boosts property value but also a crucial step towards a more sustainable future, aligning with broader home improvement goals.

Replacing outdated windows with modern, energy-efficient models is one of the most impactful upgrades a homeowner can make. Beyond immediate energy savings, energy-efficient windows contribute to long-term cost reduction and improved indoor environmental quality. For example, windows with optimal thermal performance reduce the strain on HVAC systems, extending their lifespan and minimizing maintenance costs. Furthermore, advanced features like low-E coatings and argon gas windows mitigate drafts and cold spots, creating a more comfortable and consistent indoor temperature.

This enhanced comfort can translate to increased productivity in home offices and improved sleep quality in bedrooms. When considering window replacement, homeowners should prioritize windows that meet or exceed ENERGY STAR standards for their specific climate zone, ensuring optimal performance and energy savings. The impact of energy-efficient windows extends beyond individual homes, contributing to broader sustainable building practices and community-wide energy conservation efforts. Government incentives and rebates, often available for energy-efficient window upgrades, further incentivize the adoption of these technologies.

By reducing overall energy demand, communities can lessen their reliance on fossil fuels and mitigate the environmental impact of energy production. Moreover, the increasing demand for sustainable building materials is driving innovation in window frame materials, with manufacturers developing eco-friendly options that combine thermal performance with environmental responsibility. From sustainably harvested wood to recycled vinyl, the options for environmentally conscious homeowners are expanding, making energy-efficient window replacement a powerful tool for creating a greener future. The future of windows is dynamic, intelligent, and undeniably energy-efficient.